Product Categories

Contact Us

Market Department 1 :86-186-0538-6838

Market Department 2: 86-182-5483-9668

Market Department 3: 86-156-2159-5858

Market Department 4: 86-182-5380-6958

After-sales Service Department:

86-186-0538-6838/86-186-6082-0255/86-156-2153-9898

86-182-5380-6558/86-151-6388-5858

Postcode: 271000

Address: No. 3, Wulongshan Road, Taiyue Economic Development Zone, Taian City

Email: tianchengtest@126.com

English Website: www.tianchengtest.com

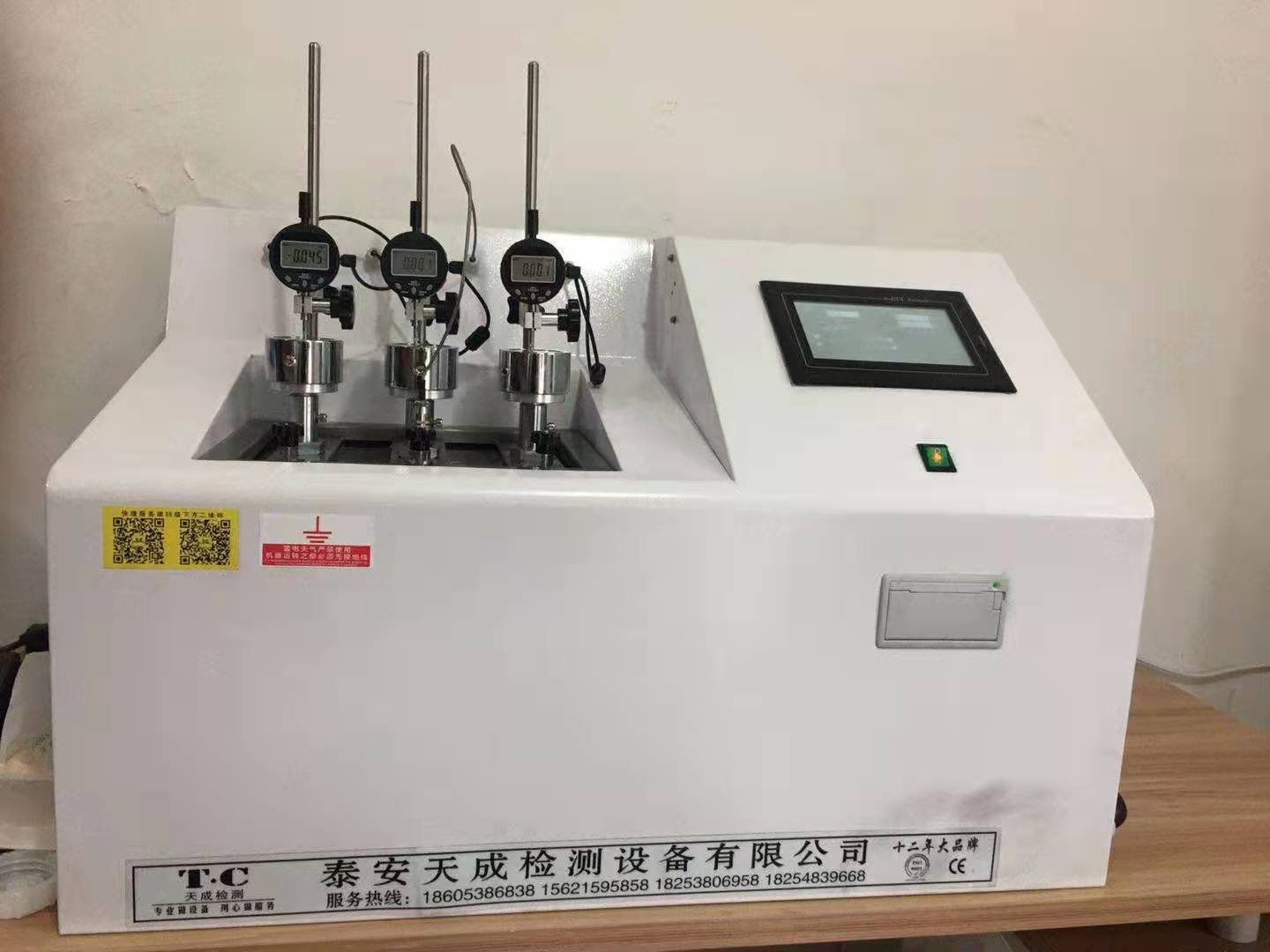

Vicat softening point tester

The Vicat softening point temperature tester is mainly used for determining the Vicat softening point temperature of non-metallic materials (such as plastics, rubber, nylon, electrical insulating materials, etc.). It is an ideal testing tool for chemical enterprises, research institutions, and colleges and universities.

Keywords:

Detailed Description

1, Purpose:

XRW-300BThe Vicat softening point temperature tester is mainly used for determining the Vicat softening point temperature of non-metallic materials (such as plastics, rubber, nylon, electrical insulating materials, etc.). It is an ideal testing tool for chemical enterprises, research institutions, and colleges.

2, Features:

2.1This instrument complies with the requirements of ISO75-1974, ISO306-1974, GB/T1633-79, and GB1634-79 standards, and can achieve real-time display, temperature control, measurement, alarm, and other functions. Notably, the XRW-300B has high temperature control accuracy and safety performance. The control core uses PLC control technology combined with a configuration interface, making operation simple and quick.

2.2 Cabinet (vertical) structure, the sample rack can be automatically raised and lowered.

3, Main performance indicators of the instrument::

3.1Temperature control range: Room temperature - 300℃

3.2Heating rate: 120℃/h, 50℃/h

3.3Maximum temperature measurement error:+0.5℃

3.4Maximum temperature control error:+1℃/6 min(Thermal deformation test)

+0.5℃/6 min(Vicat test)

3.5Maximum deformation measurement range: 1mm

3.6Number of sample racks: 3units, temperature display 3racks

3.8Heating medium: Methyl silicone oil (model --200below, flash point 300℃and above)

3.9Maximum heating power: 3kw

3.10Lifting motor power: 25W

Stirring motor power: 15W

3.11Cooling method: Air cooling above 150℃ (optional)Water cooling below 150℃ (

Main power supply: 220V10%.Water cooling below 150℃ (

3.12, 20A+, 50HZ;Automatic shutdown at the end of the test., Working principle

3.13The temperature signal sensed by the temperature sensor is input to the transmitter, converted into an analog signal and sent to the PLC

4, which provides the corresponding heating parameters through running the PID

program to control the heating time of the heater, thus achieving temperature control. When a certain sample reaches the set deformation amount, the computer sends a control signal to stop the heater's operation. To ensure that the test can be conducted safely and reliably, an "upper limit temperature" is designed. When the deformation amount has not reached the highest set value, but the temperature reaches the set "upper limit temperature", the control stops heating. This ensures the safety and reliability of the test. Without setting an upper limit temperature, the test cannot be conducted.,通过运行PID程序给出相应的加热参数,控制加热器的加热时间,从而达到控温的目的。当某一个试样达到设定的变形量时,计算机发出控制信号,停止加热器的工作。为了使试验能安全可靠的进行,设计了“上限温度”。当变形量没有达到最高设定值,而温度达到设定的“上限温度”时,文本控制停止加热。从而保证了试验的安全可靠。不设置上限温度将无法进行试验。

Get a Free Quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!