Product Categories

Contact Us

Market Department 1 :86-186-0538-6838

Market Department 2: 86-182-5483-9668

Market Department 3: 86-156-2159-5858

Market Department 4: 86-182-5380-6958

After-sales Service Department:

86-186-0538-6838/86-186-6082-0255/86-156-2153-9898

86-182-5380-6558/86-151-6388-5858

Postcode: 271000

Address: No. 3, Wulongshan Road, Taiyue Economic Development Zone, Taian City

Email: tianchengtest@126.com

English Website: www.tianchengtest.com

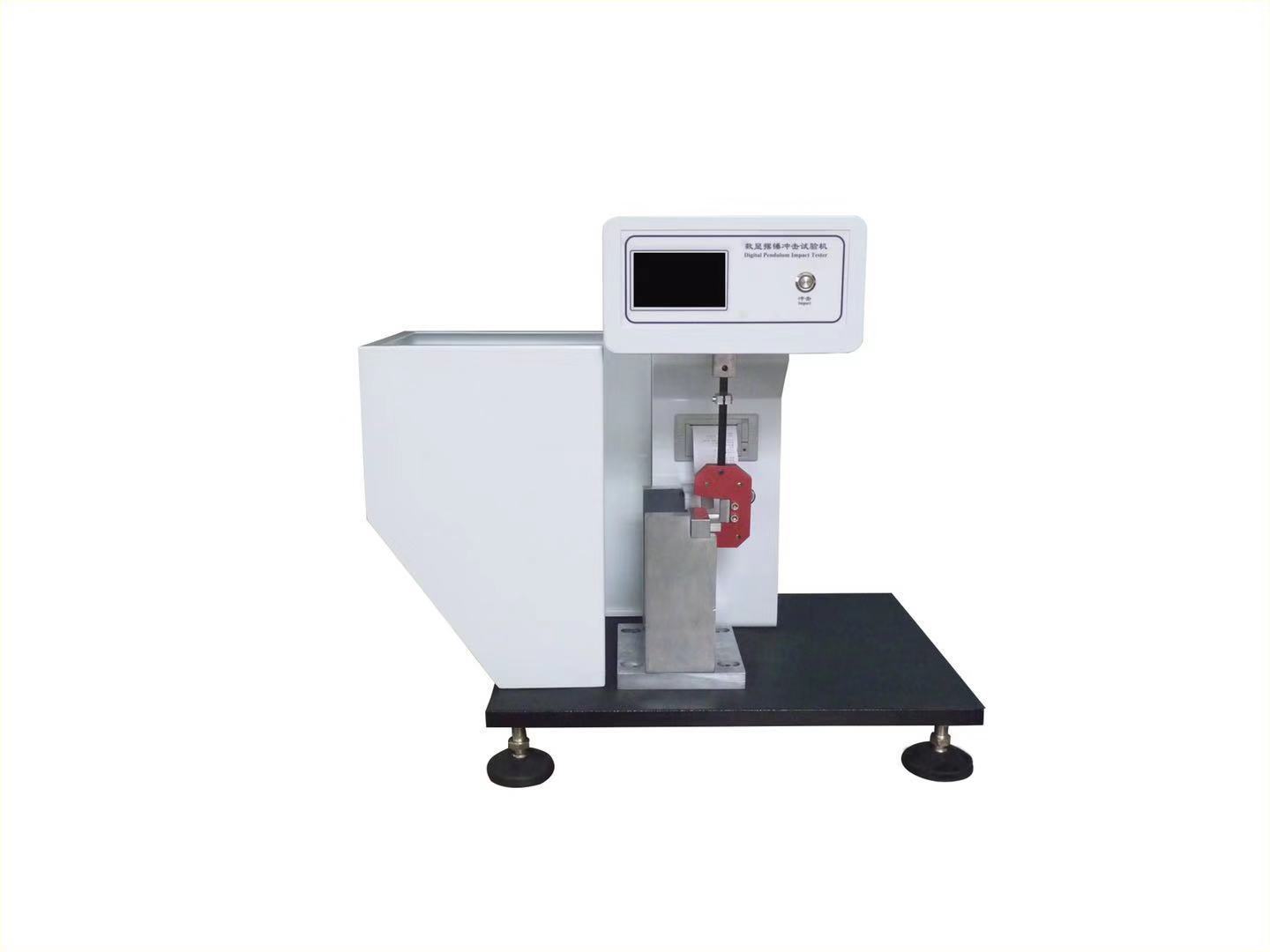

Simply Supported Beam Testing Machine

The simple beam impact testing machine is used to determine the impact toughness of non-metallic materials such as hard plastics, reinforced nylon, fiberglass ceramics, cast stone, plastic electrical appliances, insulating materials, and plastic pipes. This testing machine is available for research institutions, colleges and universities, various levels of quality inspection agencies, and material production factories for conducting impact tests.

Keywords:

Detailed Description

1. Purpose and Characteristics

XJJThe XJJ series pendulum impact testing machine is used to determine the impact toughness of non-metallic materials such as hard plastics, reinforced nylon, fiberglass ceramics, cast stone, plastic electrical appliances, insulating materials, and plastic pipes. This testing machine is suitable for research institutions, colleges and universities, various levels of quality inspection agencies, and material production factories for conducting impact tests.

Applicable Standards:ISO179-1992; GB/T1043-93; JB/T8762-1992;GB/T18743

2. Technical Specifications

1Impact Energy:15J

2Impact Speed:3.8m/s

3Jaw Support Distance:40-95Adjustment

3. Structural Overview

The testing machine consists of the main body, jaws, impact pendulum, and indicating structure.(See Figure1)

1The main body is the supporting structure of the machine.

2The jaws are components used to support the specimen. (See Figure2)

3The impact pendulum consists of an upper connecting sleeve, pendulum rod, hammer body, and impact edge. This machine has a total of4types of pendulums, which can produce4types of impact energy.

4Indicating Structure: Consists of a dial (8), active pointer (5), passive pointer (7), and friction disc (6).

4. Transportation and Installation

(1When loading and unloading the testing machine's packaging box, avoid excessive tilting and do not allow collisions or strong vibrations.

(2Before installation, the rust-proof oil applied during packaging should be cleaned off, and dust should be wiped away with clean cotton cloth. Do not disassemble any components during cleaning and wiping.

(3The testing machine must be securely fastened to the foundation and leveled. The foundation's weight must be at least40times the weight of the heaviest pendulum used.

(4The positions of the anchor screws must meet the requirements.

(5Insert the power plug into the AC220Vsocket.50Hz插座中。

5. Operating Instructions

1Turn on the power and switch on.

2Select the appropriate pendulum based on the impact toughness of the specimen. The selected pendulum should ensure that the energy consumed to break the specimen is within10%-90%范围内。注意:如果事先不能大至确定能量范围,应首先选用大能量的摆锤。

3、将摆锤安装于机器上。方法是:首先卸下摆锤上连接套(9)上的螺栓及上半部分,再将摆锤用上连接套牢固地固定在主轴上。注意:连接套上有定位销,装锤时要使定位销在主轴上的小孔中,同时装上连接套时要保持上下部分方向一致。

4、为了使冲击后指针能正确地进行工作,在试验前应使冲击摆锤处于铅垂位置,并检查被动指针是否与主动指针靠紧,被动指针的指示的位置是否处于最大能量处。(目视即可)如不重合则需松开紧固螺母,将被动指针与主动指针靠紧,使被动指针指示在最大能量处,然后将螺母紧固。

5、根据不同规格试样选用对中样板(附件,尺寸为40socket.62socket.70socket.95)调整两支撑刀刃间距。方法是松开夹紧块(19)上的螺钉,移动左右两活动刀刃底座(20)至合适位置再拧紧夹紧块(19)上的螺钉。然后选择合适的调整板,固定在刀刃底座(20)上。

松开螺栓(23),将不同规格试样放置于刀刃底座(20)上的调整板上并紧贴支撑刀刃(22),然后调整手轮(13)通过丝杆(15)使拖板(17)(钳口)左右移动至试样刚好接触自由铅垂的锤刃上,并拧紧螺栓(23),注意移动拖板时应先使其左移一部分再右移至合适位置。

6、冲击试样时将摆锤扬起,按下按钮(1),将摆锤卡住,再按下按钮(1),摆锤落下,冲击试样。

7、从表盘上读取数值或按有关方法进行计算冲击功。

试样冲击强度计算

试样冲击强度α(kJ/m2)Calculated by the following formula:

α=EX·Y×103

In the formula:E—The impact energy absorbed during the testJ.

X—The effective thickness of the samplemm.

Y—The width of the samplemm.

6. Notes and Maintenance

(1During transportation, the pendulum should be removed to avoid damage to related parts caused by the swinging of the pendulum.

(2The pendulum should be coated with anti-rust oil when not in use.

(3It is strictly prohibited to disassemble or replace related parts on the pendulum unless necessary, to avoid changes in the impact constant and striking center distance.

(4Before use, check whether the connecting screws of the pendulum rod, pendulum, etc. are loose.

(5)To ensure the minimum friction of the bearing, lubricate the shaft hole with instrument oil before the first use (or after a long period of inactivity). However, do not over-lubricate, as this will increase friction.

(6The main power supply should be reliably grounded.

Get a Free Quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!